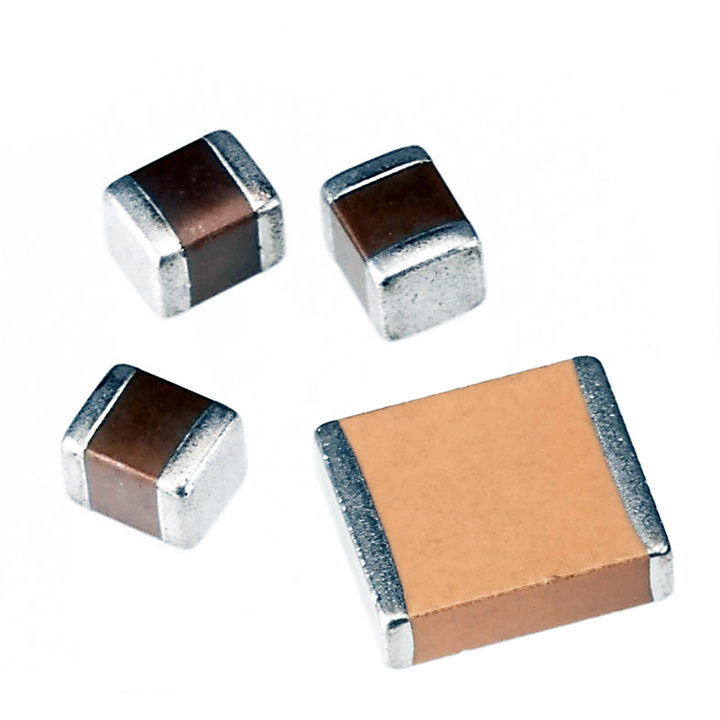

- Various temperature characteristics cover a wide range in small size.

- Mounted either by flow or reflow soldering methods.

- Excellent dielectric strength due to uniform structure of dielectric layers.

C

Introduction

General specifications

NPO Chip Ceramic Cap.

- Size _ 0201 to 2225

- Rated Working Voltage_16Vdc to 4000Vdc

- Capacitance Range _ 0.47pF to 220nF

- Operating Temp. Range_-55℃ to +125℃

- Capacitance Tolerance _

C<10pF_±0.1pF, ±0.25pF, ±0.5pF,

C≧10pF_±1%, ±2%, ±5% - Packaging_ Tape / Reel

X5R Chip Ceramic Cap.

- Size _ 0201 to 2220

- Rated Working Voltage_4Vdc to 50Vdc

- Capacitance Range _ 100nF to 220uF

- Operating Temp. Range_-55℃ to +85℃

- Capacitance Tolerance _±10%, ±20%

- Packaging_ Tape / Reel

X7R Chip Ceramic Cap.

- Size _ 0201 to 2225

- Rated Working Voltage_10Vdc to 4000Vdc

- Capacitance Range _ 100pF to 47uF

- Operating Temp. Range_-55℃ to +125℃

- Capacitance Tolerance _±10%, ±20%

- Packaging_ Tape / Reel

X6S Chip Ceramic Cap.

- Size _ 0201 to 1201

- Rated Working Voltage_4Vdc to 100Vdc

- Capacitance Range _ 0.1uF to 100uF

- Operating Temp. Range_-55℃ to +105℃

- Capacitance Tolerance _±10%, ±20%

- Packaging_ Tape / Reel

X7S Chip Ceramic Cap.

- Size _ 0201 to 1201

- Rated Working Voltage_6.3Vdc to 100Vdc

- Capacitance Range _ 0.1uF to 100uF

- Operating Temp. Range_-55℃ to +105℃

- Capacitance Tolerance _±10%, ±20%

- Packaging_ Tape / Reel

X7T Chip Ceramic Cap.

- Size _ 1206 to 2220

- Rated Working Voltage_250Vdc to 630Vdc

- Capacitance Range _ 0.01uF to 2.2uF

- Operating Temp. Range_-55℃ to +125℃

- Capacitance Tolerance _±10%, ±20%

- Packaging_ Tape / Reel

Part numbering system

Example

| 0805 | N | 102 | J | 500 | N | T |

| ①~④ | ⑤ | ⑥~⑧ | ⑨ | ⑩~⑫ | ⑬ | ⑭ |

①~④

| Code | Size |

| 0201 | 0.6X0.30mm |

| 0402 | 1.0X0.50mm |

| 0603 | 1.6X0.80mm |

| 0805 | 2.0X1.25mm |

| 1206 | 3.2X1.60mm |

| 1210 | 3.2X2.50mm |

| 1808 | 4.5X2.00mm |

| 1812 | 4.5X3.20mm |

| 1825 | 4.5X6.30mm |

| 2211 | 5.7X2.80mm |

| 2220 | 5.7X5.00mm |

| 2225 | 5.7X6.30mm |

⑤

| Code | Temperature Coefficient |

| N | NPO |

| B | X7R |

| X | X5R |

| S | X6S , X7S |

| T | X7T |

⑥~⑧

| Code | Rated Capacitance |

| 0R5 | 0.5pF |

| 101 | 100pF |

| 104 | 100nF |

⑨

| Code | Tolerance on Rated Capacitance |

| A | ±0.05pF |

| B | ±0.10pF |

| C | ±0.25pF |

| D | ±0.50pF |

| F | ±1.0% |

| G | ±2.0% |

| J | ±5.0% |

| K | ±10% |

| M | ±20% |

| Z | +80-20% |

⑩~⑫

| Code | Rated Voltage(DC) |

| 063 | 6.3V |

| 100 | 10V |

| 160 | 16V |

| 250 | 25V |

| 500 | 50V |

| 630 | 63V |

| 101 | 100V |

| 201 | 200V |

| 251 | 250V |

| 401 | 400V |

| 501 | 500V |

| 631 | 630V |

| 102 | 1000V |

| 152 | 1500V |

| 202 | 2000V |

| 252 | 2500V |

| 302 | 3000V |

| 352 | 3500V |

| 402 | 4000V |

| 502 | 5000V |

| 602 | 6000V |

⑬

| Code | Termination |

| N | Nickle Barrier with 100% Tin |

⑭

| Code | Package (Reel Q’ty) |

| 05 | 500 |

| 1 | 1000 |

| 2 | 2000 |

| 3 | 3000 |

| T | 4000 |

| U | 10000 |

| V | 15000 |

| W | 50000 |

Download

| Name | |

|---|---|

| MLCC Approval sheet |